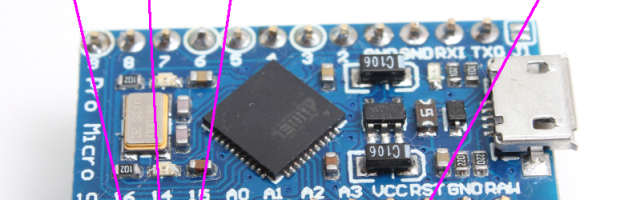

I was doing something with foolish in avrdude, ending in me killing the bootloader on my Arduino Pro Micro . The Arduino Pro Micro bootloader creates a USB connection which the user can upload code, however by overwriting the bootloader, the chip no longer enumerates as a USB device and can no longer accept new sketches. Fortunately, I hadn’t messed up the fuse bits, so I can still upload using ISP. There wasn’t much documentation on doing this for a Pro Micro, so I had to look up the data sheets for the chip and trace the Eagle PCB schematics. Fortunately, all of the ISP connections are accessible via the pin headers. I used my USBasp, but any ISP programmer including another Arduino running Arduino ISP should work.

Raspbian slow SSH fix

I had been noticing that SSH and rsync were unusually slow to connect on my Raspberry Pi running Raspbian. I had initially assumed it was due to the small CPU, but after doing some searching around, I had found that adding an extra setting in SSHd’s config fixed the problem.

in /etc/ssh/sshd_config, add:

UseDNS no

Then restart sshd with “service ssh restart”.

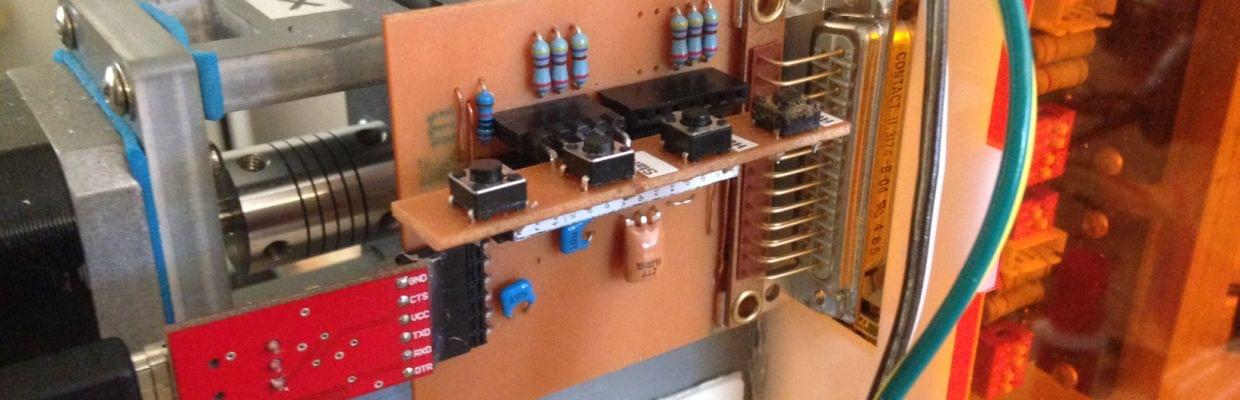

Grbl CNC USB to TB6560 Interface using Arduino

I’ve had a CNC mill for a few years now, and while many homemade CNC mills use EasyDriver or Pololu, mine came with a sturdy, generic TB6560 controller board. For those unfamiliar, boards like this are interfaced using an old fashioned LPT parallel port, which was initially an annoyance, but quickly became impractical and a hassle, having to use an old PC with VNC installed. The board has plenty of power to push the steppers around, far more than any of the smaller / cheaper solutions had to offer I think, so I wanted to try and teach this board a few new tricks, and let me interface with it using a more modern interface.

Hacking USB into an Alfa AP121 router

While checking out all the awesome things you can do with a Fon Wifi Pineapple, I thought it would be fun to grab a newer router, capable of running Pineapple Mark-IV. I found what I thought was a great deal on eBay, and upon closer inspection, I had bought an Alfa AP121, which lacks the USB it’s sister model the AP121U / Hornet-UB has. I could have resold it, but my solution was to reverse engineer it, and try to add the USB myself.

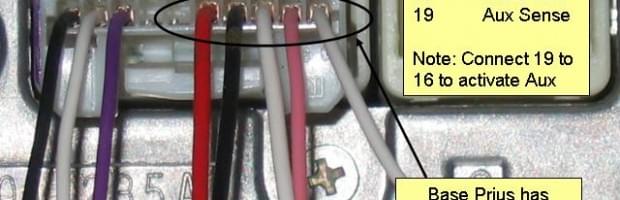

Adding a free Aux in to a 2007 Prius

Much to my dismay, the stock radio in my 2007 Prius did not include an AUX in port for hooking up an iPod. Searching around, it turns out that the 51824 in my car does have a CD changer port, and does have the AUX pins, however they don’t function. I even bought an adapter on eBay to use the CD changer port with an external source, and the stereo didn’t even take any notice of the adapter. I sent it back, and instead opted to replace the whole radio with a 51824, which does support these features.

Cracking the Sentry DS0100 Safe

I found a trashed combination safe on the sidewalk recently. Here’s a very quick, to the point method of opening it with minimal damage. I watched a few other videos and wanted to try and keep the safe undamaged, and still fully usable. After shooting the video, I filled the hole I drilled with epoxy and also used a little bit to stick the faceplate back on. In case anyone was curious, it wasn’t filled with $100 bills.

iPod Video failed capacitor

My brother recently got an iPod Video off eBay which refuses to keep a charge for longer than 30 minutes. I suspected it was an old battery, and thought it could be fixed by swapping in another one. Once I got the case open, I discovered a burn mark on the back on the hard drive foam, pointing out that there was a blown out component on the main board. Lovely.

Mill mount improvements

I found it a little annoying whenever I wanted to swap the motor mount off my Zen Toolworks CNC mill, the washers and nuts would be difficult to work with and regularly fall into the machine. I already super glued most of the washers to the mill, but to improve swapping accessories, I cut these little jigs out of 4mm acrylic to hold the bolts from turning. The photo below shows the jigs with the nuts not inserted yet. Once the mill is reassembled, I only need to deal with the accessory I am attaching, and the four bolts used to hold it down. Much easier!

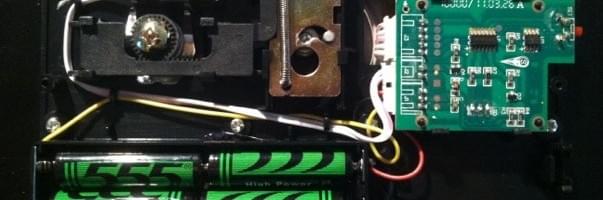

Cracking the lock box

A few days ago we were driving through Ukiah, CA, and wanted to check out the local pawn shop. They had a digital lock box which was missing it’s keys and had an unknown code. I shook it and, it didn’t seem to have anything heavy inside, but it did sound like there were keys inside. I haggled with the salesman and bought it for $12 plus tax.

CNC cutting vinyl stickers

I bought a Roland blade holder on eBay, which is mean to be placed in a pen plotter. People have had good results in using it in their CNC mills. I found a number of photos of other setups, but they were either attached with no spring pressure, or far too over engineered. Since I want to play with laser cutting later, I made the assembly hold both laser and blade cutter. The assembly created in Google SketchUp, exported into CamBam, then was cut out of ~4mm thick cast acrylic using the CNC mill. The assembly replaces the motor mount on the CNC.

To properly cut, the blade has to have some spring loaded pressure into the rear of the blade holder. This allows the blade to float across the work surface with a constant amount of pressure. There were a lot of ideas on how to do this on the internet, but I came up with a cheap quick solution by reusing parts from two ball point pens. So far, the results have been great! I zero the Z axis with the blade just touching the vinyl, then cut at -0.3mm.