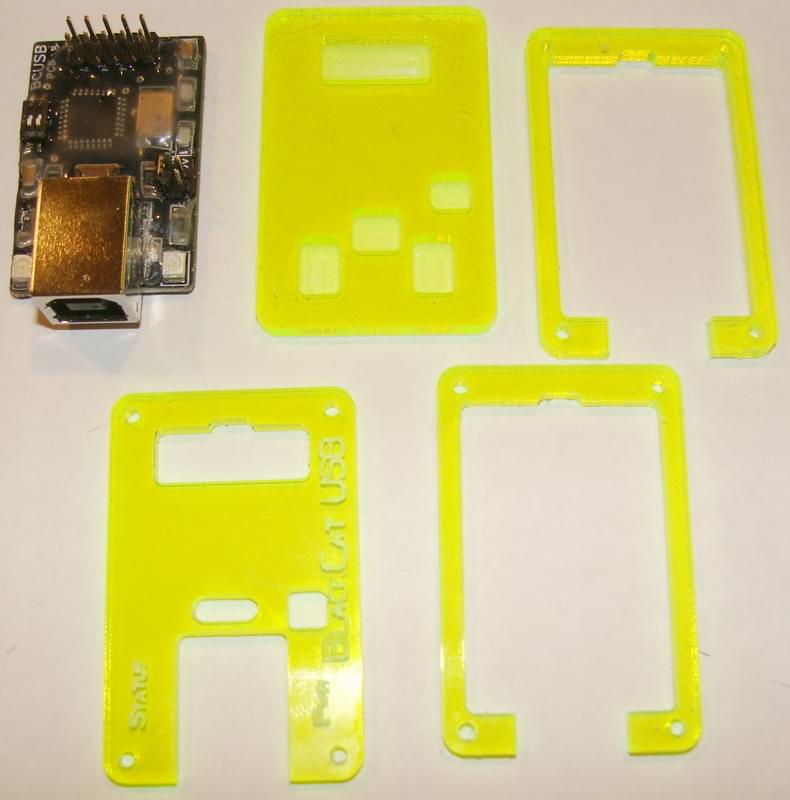

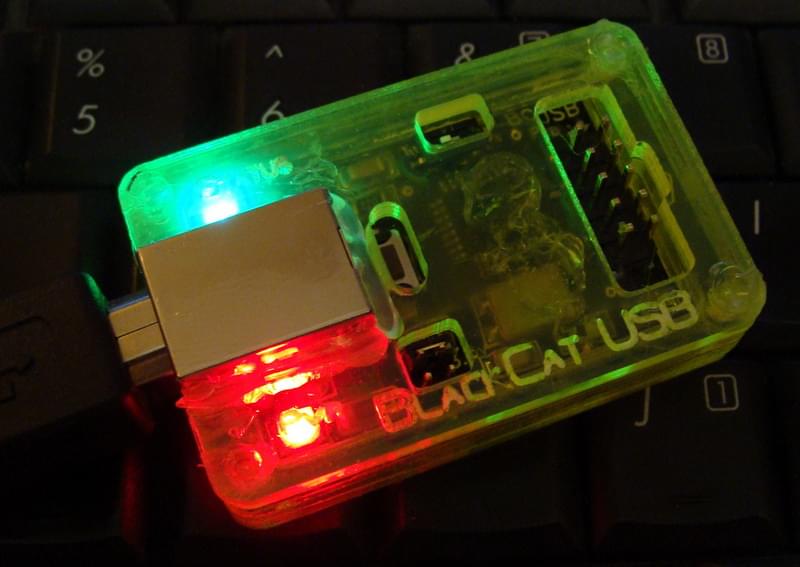

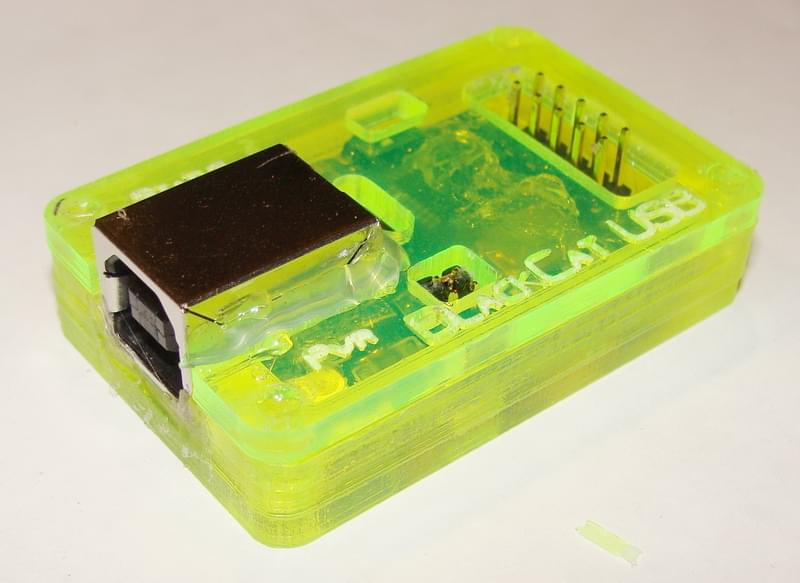

Like the BusPirate case I recently made, I have a lot of these PCBs that are fragile and I worry will be damaged by every day use, and even storage in my drawers. I went with a slightly thinner cast acrylic and included a few new concepts in the design. First, I used a v-carve bit and engraved writing into the case front. While it is legible, I think it would have been better if I had carved into backside of the top piece. Second, on the bottom section, I made recessed cutouts as so the board can sit flat on the bottom of the case. Lastly, I used holding tabs on the two middle sections, as so they stay put while the cutting is happening. On the BusPirate mill, the middle “C” parts were moving around due to their flimsy shape. I’ve updated the files to reflect my adjustments and observations in the case I already milled which is pictured. If I decide to re-mill it, it should fit much better and look better.

As before, the case is made from cast acrylic, joined using Weld-On acrylic solvent. I wanted to attach the top part using screws, but I drilled the holes too large. I think they are fixed in the new gcode.