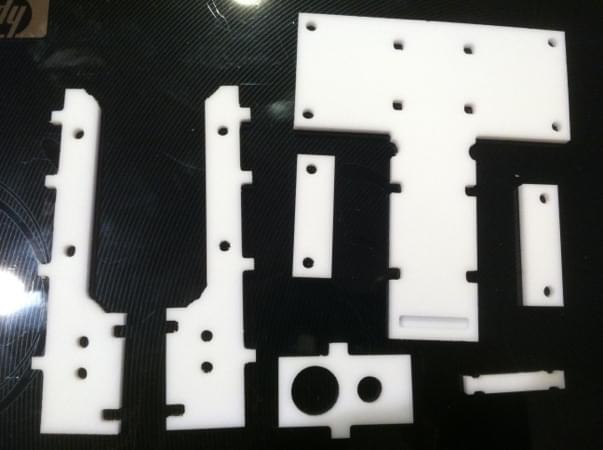

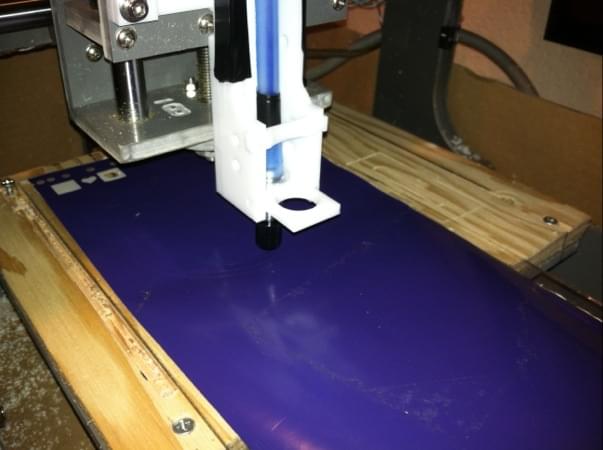

I bought a Roland blade holder on eBay, which is mean to be placed in a pen plotter. People have had good results in using it in their CNC mills. I found a number of photos of other setups, but they were either attached with no spring pressure, or far too over engineered. Since I want to play with laser cutting later, I made the assembly hold both laser and blade cutter. The assembly created in Google SketchUp, exported into CamBam, then was cut out of ~4mm thick cast acrylic using the CNC mill. The assembly replaces the motor mount on the CNC.

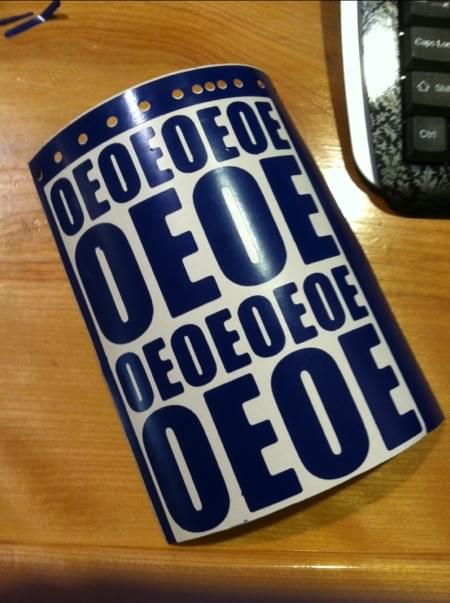

To properly cut, the blade has to have some spring loaded pressure into the rear of the blade holder. This allows the blade to float across the work surface with a constant amount of pressure. There were a lot of ideas on how to do this on the internet, but I came up with a cheap quick solution by reusing parts from two ball point pens. So far, the results have been great! I zero the Z axis with the blade just touching the vinyl, then cut at -0.3mm.